Introduction: More Than Just Minor Tweaks

It’s a common perception that building legislation moves at a glacial pace. Years of consultation often lead to minor adjustments that barely register on the industry’s radar. However, the ground is shifting beneath New Zealand’s built environment. A series of rapid, fundamental changes are currently reshaping how buildings are designed, consented, and constructed.

At a recent industry conference, Matt Bishop of Brevity Engineering distilled the most surprising and impactful of these new developments. This article unpacks five of the most significant changes he outlined, providing a clear guide to a new and evolving regulatory landscape.

Navigating Major Changes in the NZ Building Legislation (AWCI Conference 2025)

Navigating Major Changes in the NZ Building Legislation (AWCI Conference 2025)

The 5 Most Impactful Changes Unpacked

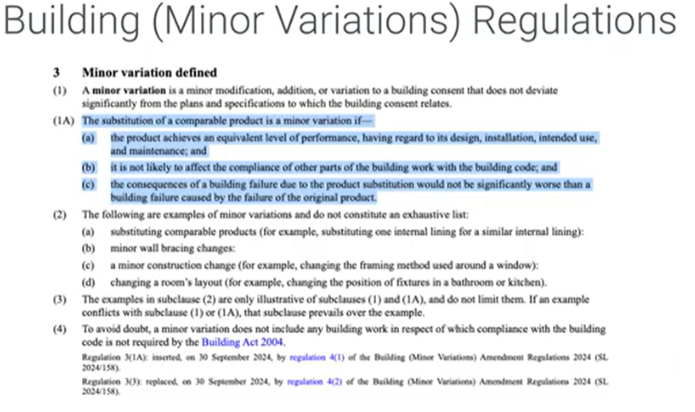

1. The ‘Like-for-Like’ Rule for Product Swaps Is Over

A significant change to the “minor variations” regulation—the September 2024 minor variations, to be exact—slipped in, fundamentally altering how product substitutions are handled on-site. Previously, a minor variation was typically interpreted as a “like-for-like” product swap—for example, replacing one brand of 64x.75 steel stud with another of the exact same dimensions.

The new regulation redefines this concept to “like-for-like performance.” This means a substitution is considered minor if the new product achieves an equivalent level of performance. For instance, a 64x.75 steel stud could be swapped for a differently sized 92x.55 stud, provided the new stud can take the same structural load.

The impact of this is profound. It streamlines on-site substitutions by allowing for comparable products without triggering costly and time-consuming consent updates or engineering re-designs. While this is a major efficiency gain for the industry, it also removes a source of “nice profit” that engineers previously made on rework, signaling a significant operational shift.

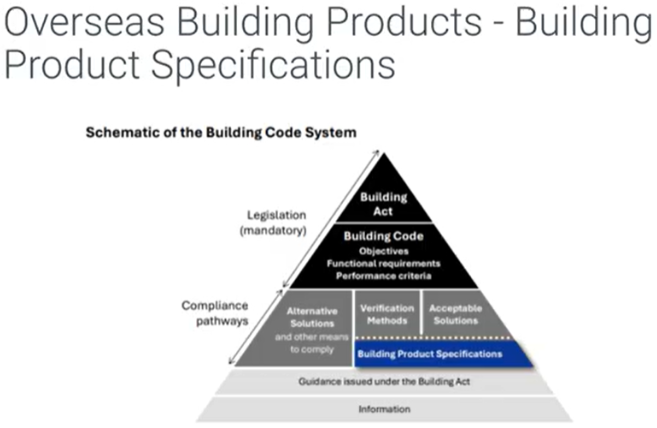

2. Overseas Building Products Are Getting a VIP Pass into New Zealand

The Overseas Building Product amendment is set to be a major game-changer for product specification and procurement. The most critical part of this new legislation is the scheme for “recognised products certified overseas.”

Under this scheme, building products that have certain recognised overseas certifications—such as Australia’s WaterMark for plumbing systems—will be “deemed to comply” with the New Zealand building code automatically. This eliminates a significant barrier to entry for a wide range of international products.

“This is the big one and I like what’s happening there.”

The significance of this cannot be overstated. It will drastically simplify the process of importing materials, broaden the range of products available to the New Zealand market, and potentially allow specific systems, such as those that have undergone tracklok testing to the stringent California hospital design guidelines, to be used here without requiring expensive and redundant local re-testing.

3. Your Local Council Is No Longer the Only Consenting Authority in Town

The role and operation of Building Consent Authorities (BCAs), which are typically city and district councils, is undergoing a profound transformation driven by a convergence of regulatory and commercial pressures.

First, the liability model is shifting from “joint and severable” to “proportionate.” Previously, a council could be held liable for the entire cost of a building failure, even if they were only partially at fault. Under proportionate liability, they will only be liable for their specific share of the fault, significantly reducing their overall financial risk.

Second, a new competitive landscape is emerging. Nationwide companies, such as supermarket chains, are now tendering their consent work across the country. This has led to councils like Christchurch competing directly with Auckland Council to process consents for projects located in Auckland.

Third, the very model of public-only consenting is being challenged with the emergence of New Zealand’s first private building consent authority. Together, these changes mean BCAs are becoming less risk-averse, more commercially competitive, and are no longer a regional monopoly. This will fundamentally alter how they operate, likely leading to more streamlined and business-focused services.

4. You Now Have to ‘Choose Your Own’ Seismic Standard

In response to updates in the national seismic hazard map, a new technical specification for seismic design, TS1170.5, is being introduced. However, in a counter-intuitive move, this new specification will not replace the existing standard, NZS1170.5. Instead, TS1170.5 will be introduced as an alternative method for building code compliance.

A major technical update within TS1170.5 is the removal of the “importance level” concept. This is being replaced with a new three-column matrix for determining design levels, a fundamental shift that engineers must get up to speed with.

The direct consequence is that clients and their design teams must now choose which standard to use. This is likely to confuse clients, as it won’t always be clear which standard provides the more cost-effective design until a project is well underway. For many interior projects, the end design may be similar, as the Z factor changes are often offset by new ductility factor changes, but all existing calculators and methods will need updating.

5. The New Seismic Goal: Not Just Standing, But Repairable

A philosophical shift is underway in seismic engineering, driven by the new “Low Damage Seismic Design Guidelines.” While an initial volume has been released outlining the concept, the detailed technical guidelines required for implementation are still forthcoming and expected later this year.

The core focus is expanding beyond merely ensuring a building’s structural survival in an earthquake to ensuring its repairability in the aftermath. This new approach requires designers to factor repair costs directly into the initial design methodology. The practical goal is to prevent the kind of damage that can render a building unusable even if it remains structurally sound, such as widespread “cracking in drywall in partitions or ceilings.”

This forward-looking change is expected to create significant demand for new products and innovative methods for attaching non-structural interior elements to the main structure. It represents a move towards more resilient buildings and will drive innovation across the sector, particularly for hospitals, schools, and high-end commercial projects.

Conclusion: Opportunity in Uncertainty

The changes sweeping through New Zealand’s building industry are not minor tweaks; they are fundamental shifts in liability, competition, design philosophy, and product procurement. This new environment will inevitably lead to uncertainty and potential for disputes.

However, it also creates massive opportunities for those who can understand and adapt quickly. The core message is clear: this is an era that is risky but also an opportunity like all things. For industry professionals, the final takeaway is a call for diligence and awareness: Watch your product specifications and contracts.

Connect with Brevity!

AI in construction workflows: how it is reshaping construction delivery

AI in construction is shifting from generic productivity to embedded workflows. Firms using AI in delivery now gain…

Construction Standards Compliance: Why Clarity Is Now a Competitive Advantage

As construction standards evolve, clarity in compliance is becoming a competitive advantage. Firms that interpret and…

Brisbane 2032 Olympics Construction and the Shift Reshaping Interiors Delivery

The Brisbane 2032 Olympics is reshaping the construction industry by compressing timelines, intensifying compliance,…