When you’re outsourcing steel production overseas, ensuring the material quality can be tricky. Unfortunately, relying on mill certificates alone isn’t always enough, as they can sometimes be forged or inaccurate. That’s where hardness testing comes in. It’s a simple, cost-effective way to get some immediate insight into whether the material you’re receiving lives up to the claims made by your supplier.

Why Hardness Testing is Key

Hardness testing is a quick way to verify that the steel you’re receiving has the strength and quality you need. Hardness is directly linked to tensile strength, so if the steel passes a hardness test, there’s a good chance it’s up to par in terms of how much force it can handle before breaking.

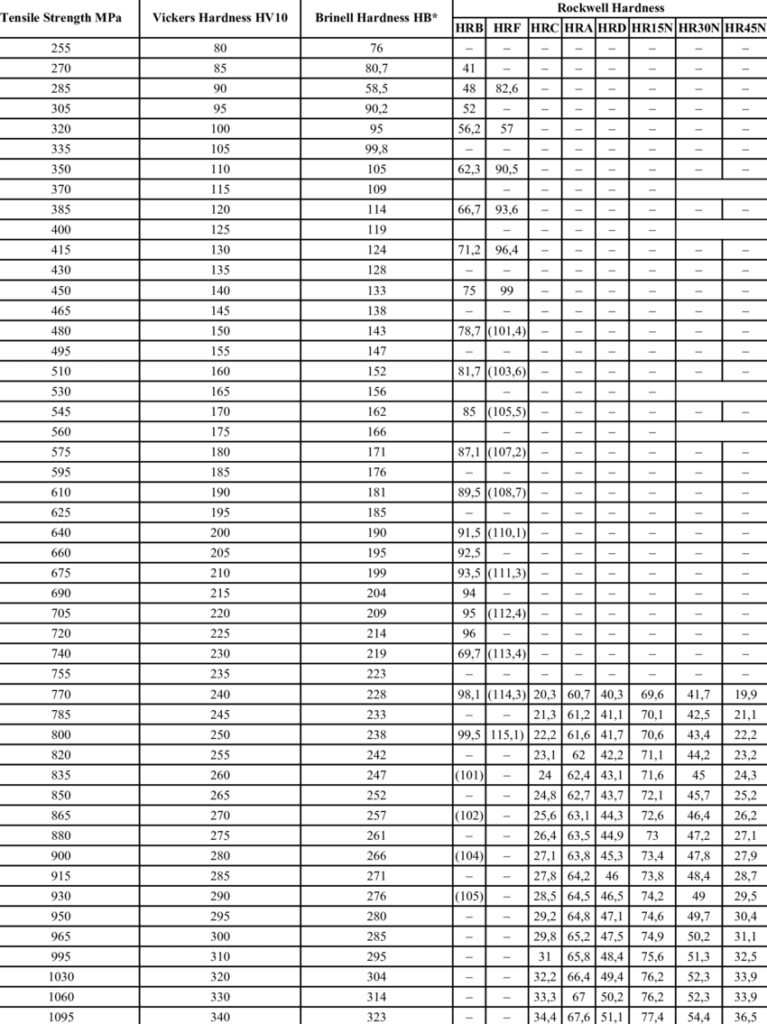

A Leeb hardness tester is one of the easiest tools to use for this. It’s portable, affordable, and provides fast, reliable results. Essentially, it drops a small object onto the material and measures how much the object bounces back. The rebound speed tells you the hardness of the steel. Simple, right? And because it’s non-destructive, you don’t have to worry about ruining a piece of material while testing it. Here’s an example of a comparison chart from UNI EN ISO 18265 standard for unalloyed and low alloy steels and cast steels:

A “Gateway” Test

However, we recommend thinking of hardness testing as a “gateway” test. It’s a great first step to verify the quality of your steel, but it shouldn’t be the last step if something seems off. If the hardness test results don’t align with the claims on the mill certificate, that’s a red flag. At that point, more thorough tests like tensile strength, chemical analysis, or impact testing are worth the investment.

The key here is that hardness testing is quick and easy to do, making it a solid first line of defense. It helps catch any major discrepancies early on, so you’re not blindsided by material failures further down the line.

Know the Limitations

While hardness testing is a great tool, it does have its limitations. For starters, it’s a surface-level test, so it won’t tell you if there are issues deeper within the material. It also won’t reveal problems like fatigue or brittleness. Another thing to keep in mind is that surface conditions—like coatings, roughness, or contaminants—can affect the results, so you want to make sure the steel is clean before you test.

Why We Recommend Hardness Testing as Best Practice

When you’re working with international suppliers, having a quick, inexpensive way to verify material quality is essential. Hardness testing lets you spot check the quality of the steel you’re receiving without needing to invest in heavy-duty lab equipment. It’s fast, reliable, and if you catch any inconsistencies, it’s a sign to dig deeper and do more extensive testing before you accept the shipment.

In short, making hardness testing part of your regular quality checks is a smart move. It helps you ensure you’re getting what you paid for, and if something doesn’t add up, you can address it before it becomes a bigger problem. For anyone outsourcing steel production, it’s a best practice we’d highly recommend.

Fall Arrest Systems: How Fall Protection Compliance Differs Between Australia and New Zealand

While both Australia and New Zealand adhere to similar fall protection standards, their approaches to enforcement and…

Rethinking Seismic Anchors: A Smarter Approach for Interiors Engineering

Explore how Brevity is leading a smarter approach to seismic anchors in interiors engineering—balancing compliance,…

Navigating Interiors Engineering Challenges in New Zealand’s Education Sector: Key Considerations for Architects

Designing interiors for educational facilities in New Zealand requires a precise balance between safety, functionality,…