Brevity is always researching and exploring the latest technology trends and international advancements. We then consider how we can apply them to our own methodologies, consistent with our commitment to value engineering.

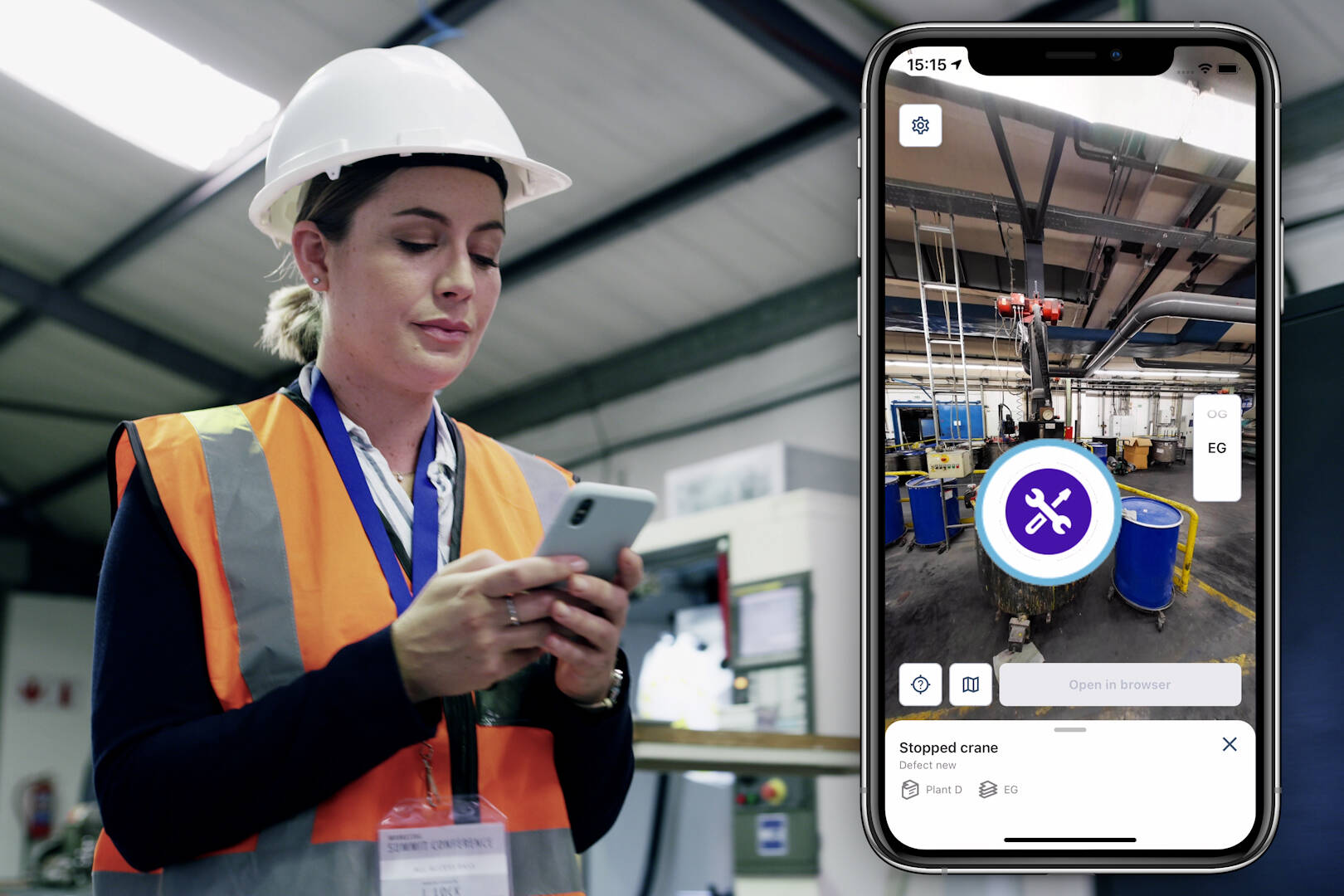

The latest of which is the use of 3D-capture technology, the Matterport. Matterport’s unique technology enables us to scan buildings more effectively and provide our clients with a highly accessible and interactive overview of their projects and/or property portfolio.

So how does it work?

Our engineers can map the built environment they are working in, for example, the interior of a multilevel commercial redevelopment, warehouse or retail environment. Matterport then creates a “photo-model” of the space, producing a doll’s house view, a conceptual layout or map. And here’s where it gets exciting. You can then click on any part of the model and walk through the site in the same way you’d navigate a Google map street view. This technology can also be viewed using virtual reality goggles.

The advantages of this technology are immediate: our engineers can virtually explore an area from anywhere, anytime after a site inspection. This helps to eliminate down time; keeping projects on track, turning results around faster and increasing our team’s efficiency. It also allows for us to show our clients where on-site issues are, without having to arrange a physical site inspection. From there, an additional Matterport scan can be done to ensure any issues identified have been remediated within an agreed time frame.

What do we love most about this technology?

Our clients do not require any specialist technology to view the Matterport scans. We simply email them a link. If we wish to have the management team or Board of company experience the full 3D ‘walk through’ of a site, the models can easily be exported to common software like Spaceclaim or Revit for further conceptual design. We find users, engineers and clients alike, gain a superior understanding of an existing space or concept by immersing themselves in a Matterport model instead of looking at potentially outdated, plans and static photos.

How are we currently implementing this technology?

Matterport’s strengths are currently being showcased in our partnership with a major NZ retailer and food distributor, who look after over 50% of the grocery market and manage more than 680 stores and wholesalers across New Zealand. Brevity have been engaged to review their network as NZ’s leading seismic engineering consultancy.

Starting with 20 locations, Brevity have commenced a pilot program to map each individual site. We have two full-time engineers on the ground currently performing in-depth inspections with Matterport. Simultaneously, an additional team of engineers is stationed at BVT headquarters to perform high-level analysis. At present, our headquartered engineers are using collected data, including level heights, bay lengths, and member specifications, to analyse racking, approximate load and function for potential areas of improvement.

Our client’s proactive approach to future-proofing, combined with our expertise in utilising leading-edge technology, has the potential to result in reduced legal and insurance exposure, as well as a competitive advantage in terms of lessened disruption of service (and associated costs) in the case of earthquake activity. We have strong interest from across the architectural, engineering and construction industry particularly with the increased number of international investors and commercial developers entering the NZ market ahead of APEC and the America’s Cup in 2021.

AI in construction workflows: how it is reshaping construction delivery

AI in construction is shifting from generic productivity to embedded workflows. Firms using AI in delivery now gain…

Construction Standards Compliance: Why Clarity Is Now a Competitive Advantage

As construction standards evolve, clarity in compliance is becoming a competitive advantage. Firms that interpret and…

Brisbane 2032 Olympics Construction and the Shift Reshaping Interiors Delivery

The Brisbane 2032 Olympics is reshaping the construction industry by compressing timelines, intensifying compliance,…