On May 7, 2024, Brevity hosted the seventh episode of our technical webinar series, focusing on the newly drafted Technical Specification TS 1170.5. This episode was a significant discussion, particularly for those involved in interiors engineering and seismic restraint design. The webinar featured a 15-minute interview with Matt Bishop, the founder and visionary of Brevity, conducted by Gye Simkin.

Introduction to TS 1170.5

TS 1170.5 represents an important update in earthquake design actions for commercial interiors. Unlike traditional updates, this specification allows for practical testing and feedback before it becomes part of the New Zealand building code. This innovative approach ensures that the new standards can be assessed for commercial viability and effectiveness.

Key Changes in Seismic Design

The primary aim of TS 1170.5 is to incorporate recent findings from the national seismic hazard model. This model has highlighted varying seismic risks across different regions, necessitating updates to existing seismic design practices. Matt Bishop explained that the new specification would impact areas with higher seismic risks more significantly, requiring more robust and resilient designs.

Implications for Interiors Engineering

For professionals in interiors engineering, particularly those working on seismic restraint, TS 1170.5 offers both challenges and opportunities. Regions such as Wellington, where seismic risks have been re-evaluated as higher, will see increased design requirements and potential cost implications. Conversely, areas like Auckland and Christchurch might not experience significant changes, allowing for more cost-effective designs in line with the new methods.

Adoption and Feedback Timeline

The draft of TS 1170.5 was released for public comment last month and is expected to be officially published later this year, around November. This draft will be introduced as an alternative solution, enabling designers to choose between the existing NZS 1170 and the new TS 1170.5. This “test drive” period, expected to last one to three years, will allow the industry to evaluate its practicality and provide necessary feedback.

Practical Insights for Engineers

Matt Bishop highlighted that the new standard provides engineers with flexibility. During the trial period, designers can utilise TS 1170.5 where it offers clear advantages and continue using NZS 1170 in other cases. This dual approach will facilitate a smoother transition and ensure that any commercial impacts are thoroughly assessed and addressed.

Balancing Challenges and Opportunities

One of the key challenges mentioned by Matt is the need to reconcile different ductility factors across various standards. However, the new specification also presents opportunities, such as the ability to incorporate specific building responses into part designs. This can potentially lower part accelerations and improve cost efficiency, particularly for components with unique response characteristics.

The Importance of Industry Feedback

The extended feedback period for TS 1170.5 is crucial for its successful implementation. The industry’s input will help balance scientific and engineering calculations with commercial realities. For instance, the inclusion of a Reserve Strength Factor in the new standard aims to account for the inherent strength of components, allowing for more precise and safer designs.

Conclusion

The introduction of TS 1170.5 marks a significant advancement in interiors engineering and seismic restraint design. Brevity is committed to staying at the forefront of these developments, ensuring that our clients benefit from the latest and most effective engineering practices. We encourage all professionals in the field to stay informed and participate in the feedback process.

For more details and updates, follow Brevity on LinkedIn and stay tuned for our upcoming webinars and articles.

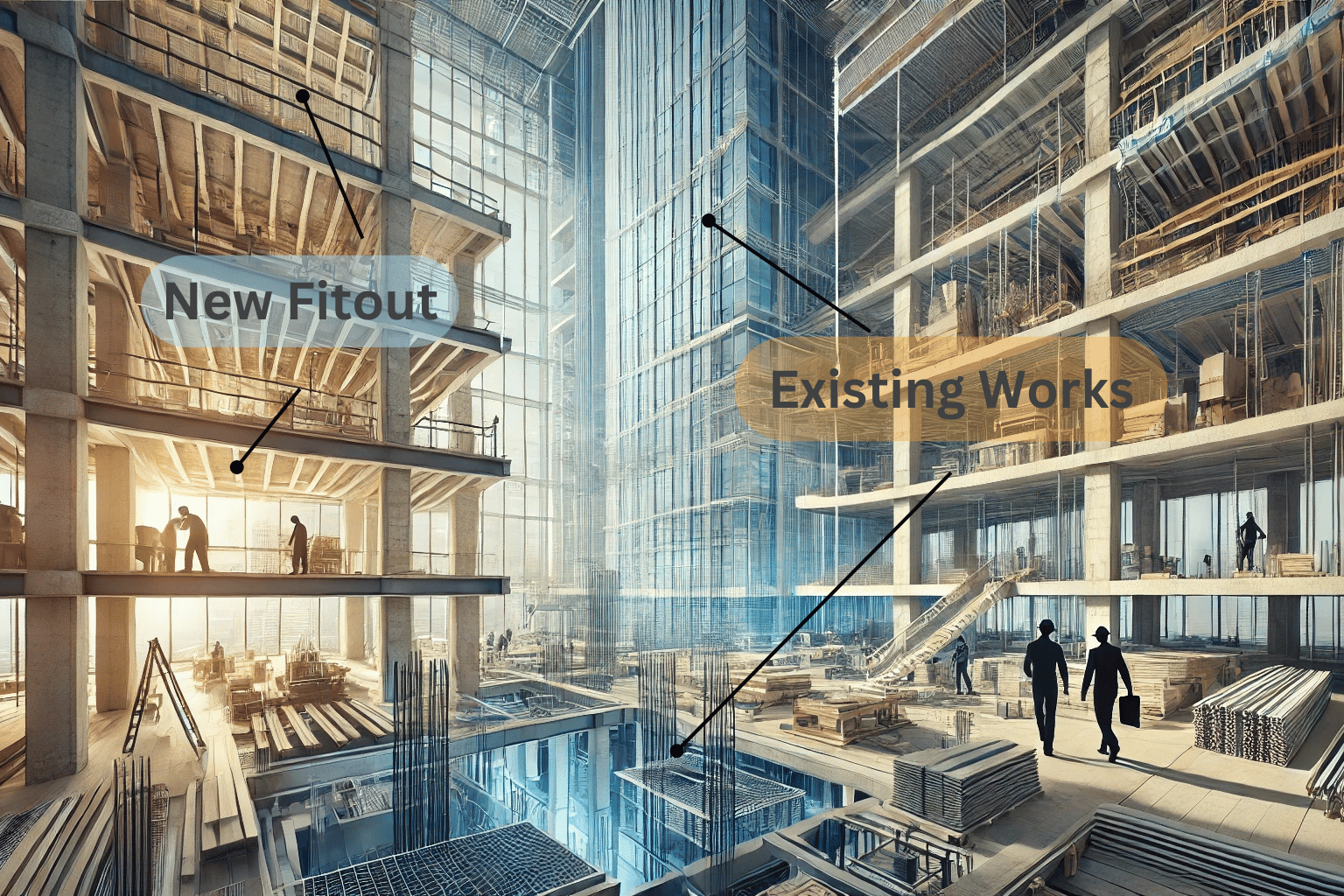

How to handle seismic rating for existing fit-out and building code compliance for new fit-out

Managing seismic safety in building projects can be complex, especially when dealing with both new and existing…

Understanding the 2024 Updates to the AWCI Code of Practice for Suspended Ceilings

What are the key updates to the 2024 AWCI Code of Practice for suspended ceilings? As discussed by Matt Bishop and Gye…

Hardness Testing: A Best Practice for Outsourcing Steel Production

When outsourcing steel production overseas, ensuring material quality can be a challenge, and relying on mill…