Waikeria prison redevelopment is a project of national importance and Brevity is proud to have played a key role, contributing our expertise to ensure the highest standards of safety and design. As the project comes to a close, we catch up with Wadsworth’s Quality Assurance Engineer, Suhesh Madathil to discuss the scale of the project and the unique aspects of working in a high security environment.

Waikeria prison development is creating a 500 bed facility with an additional 100 beds in a mental health and addiction unit. The redevelopment was announced in 2018 with construction beginning the following year. Covid 19 disruptions and supply chain pressures have made for a challenging environment, however, the project is now on track for completion in November this year.

Welcome to Aotearoa!

The Waikeria Prison project is a first for both Suhesh Madathil and Wadsworth Contracting. Wadsworth Contracting is a long established commercial fit out specialist company in Australia, with the Waikeria Prison being their first project in New Zealand. For Suhesh, it was also his first role in New Zealand, having left his career as a civil engineer in India for a new life in Aotearoa. He’s spent the last 3 years working on the project as a Quality Assurance Engineer, and says it has been a fascinating and rewarding experience.

Project Scope – Brevity contracted by Wadsworth Contracting

The redevelopment of Waikeria Prison includes 28 separate buildings, including prisoner accommodation, a mental health facility, rehabilitation programme rooms, staff training rooms and administration rooms. The majority of the structural construction is complete, with the internal fit outs and services work currently underway. Brevity’s team of professional engineers have been involved since 2020, having been engaged by Wadsworth Contracting to provide the interior seismic construction monitoring and construction design support for the project.

Brevity engineer, Sury Salunkhe, has been leading the non-structural engineering construction monitoring, working closely with Wadsworth’s Quality Assurance Lead, Suhesh Madathil, through the construction monitoring process.

A Project with a Difference

Working on a prison site has its unique aspects, Suhesh says. One of the first experiences was a training session given by the Corrections Department, before his role began. This involved outlining the various policies and processes onsite contractors needed to be aware of. As prisoners would be working alongside the contractors onsite, there were specific procedures workers needed to be aware of for safety and security purposes.

No Photography Allowed

As is common in prison construction, contractors are restricted from taking photos of the project to maintain the security and integrity of the facility. It ensures that sensitive information about the prison’s design and operations is protected, safeguarding the safety of staff, inmates, and the public.

However, as Sury is based in Auckland and conducted his construction monitoring with Suhesh remotely, the use of photographs was essential. Suhesh was given dispensation to take photos of work as it was completed to allow for remote inspections to take place.

These remote inspections were crucial to the progress of the construction as they kept the project moving quickly. As soon as one part was completed, Suhesh could photograph it, make any required remediations and keep going. This meant work was not held up waiting for Sury to conduct site visits from Auckland, which would have significantly slowed the process.

Added Levels of Fire Protection

Throughout the design and build of the prison, additional levels of security and protection were built into the design and construction. Suhesh discusses the need for fire-rated walls throughout much of the prison. He explains the purpose of fire walls to resist the spread of fire and to also maintain the structural integrity, providing more time to respond to the fire. Given the restricted ability for inmates to move freely throughout the prison, fire-rated walls provide more time for emergency responders to evacuate everyone safely. Fire-rated walls also help protect the structure of the building in a fire, which is important in a prison where the integrity of the buildings is important for security purposes.

As a result, Waikeria Prison has multiple locations with fire rated walls, which require inspection throughout the construction process to ensure they meet the quality and regulation standards.

Detailed down to the last screw

Keeping up with the technical detail of a project the size of Waikeria Prison requires an exceptional level of organisation and process. Every fitting, from windows, to furniture, to light fittings – down to every screw used, must be secure, tamper-proof, durable, and often resistant to vandalism or misuse. In his Quality Assurance role, Suhesh has been documenting check-sheets for each stage of the build. To manage the detail of this, the project has been divided into lots which are checked and signed off through a thorough process, ensuring that all aspects of the project meet specified quality standards and comply with regulatory requirements.

Teamwork

Despite the length of time this project has been running for, Suhesh has gained satisfaction from the progress and quality of the work. He has also enjoyed working alongside Sury as the build progressed, and the construction monitoring has taken place. He describes Sury as friendly and easy to work with. They have excellent communication and Suhesh gives the remote inspection process a big thumbs up, saying it made a huge difference in keeping the project moving at pace.

Sury and the team at Brevity have also enjoyed the experience of working with Suhesh and the wider Wadsworth organisation, praising their professionalism and communication. Through their teamwork, Sury and Suhesh have ensured that all aspects of the project are executed to the highest standards of quality and safety, contributing to the completion of a project that will provide important correction services for the region.

Navigating Interiors Engineering Challenges in New Zealand’s Education Sector: Key Considerations for Architects

Designing interiors for educational facilities in New Zealand requires a precise balance between safety, functionality,…

A Unified Step Forward: Strengthening Seismic Resilience in Building Design

Two key documents, the AWCI Code of Practice for Suspended Ceilings and the BIP Code of Practice for the Seismic…

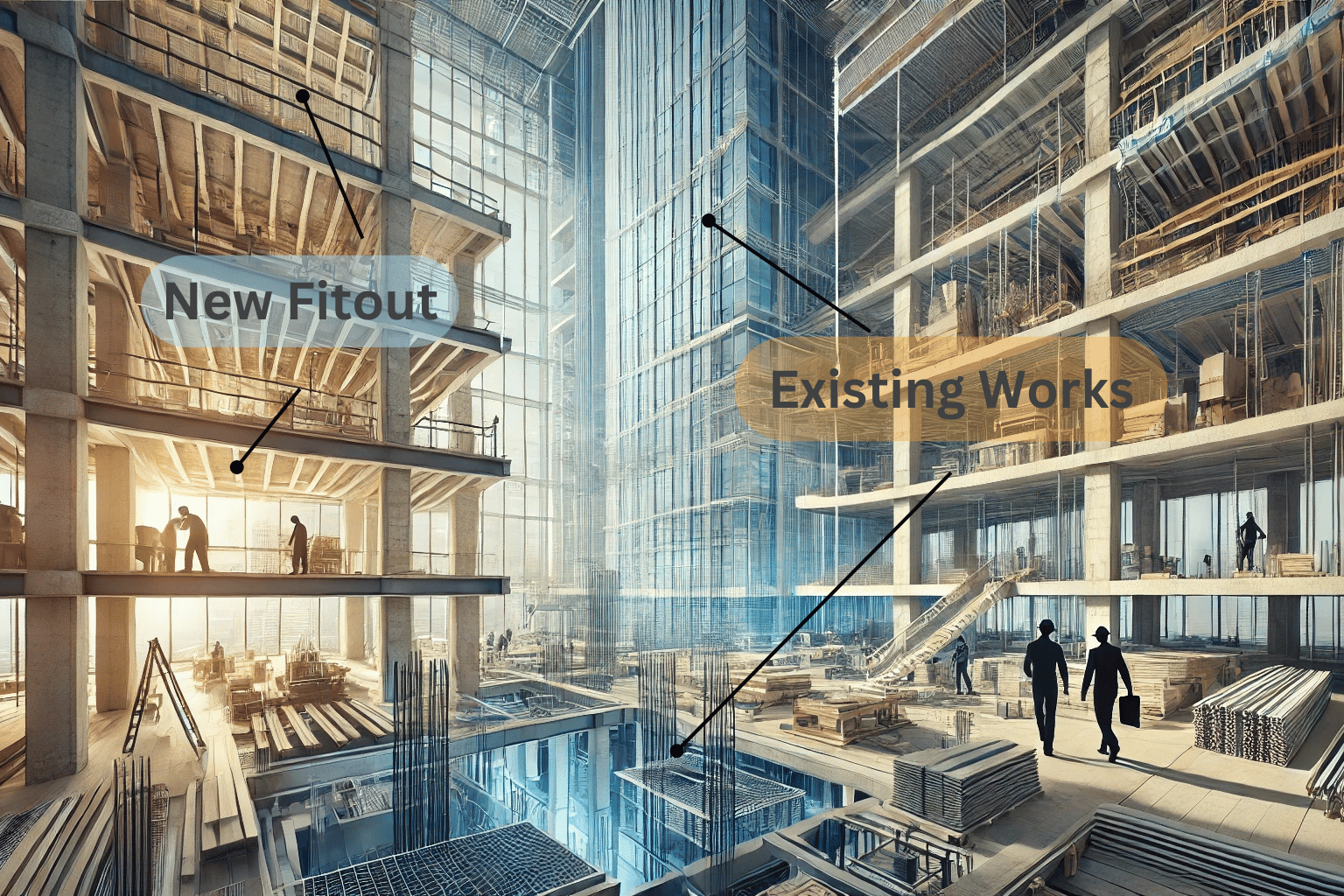

How to handle seismic rating for existing fit-out and building code compliance for new fit-out

Managing seismic safety in building projects can be complex, especially when dealing with both new and existing…