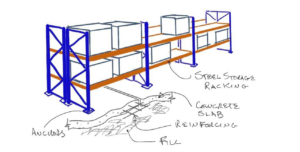

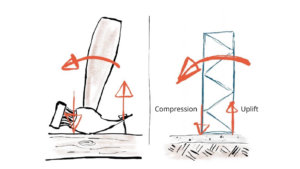

The concrete slab and fill is an important part of the pallet racking seismic structural system. Because of the tall, slender shape of pallet racking, even low seismic loads can create high compression and uplift forces in the slab, similar to the leverage caused when you use a hammer to pull a nail.

If the slab is not strong enough to resist these forces the racking may tip in a seismic event, causing a risk to the safety of people nearby as well as loss of the contents on the rack and extreme damage to the racking itself.

The normal reason that slabs have insufficient strength is a lack of thickness or adequate reinforcing. This can occur in older buildings built to earlier seismic codes, or newer buildings where the slab has been designed for traffic and storage, but not for pallet racking and seismic loading.

What to do about it?

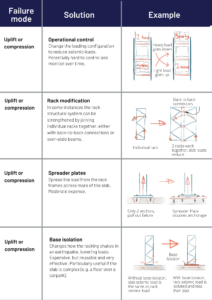

The following matrix summarises the most common solutions to remediate a slab or racking system that fails due to a weak slab:

If you have any concerns about your current pallet and racking systems, we’d love to hear from you. Balancing the performance of the rack with the cost of retrofit, the potential disruption to operations and your specific future requirements is a complex task. It’s one which we’ll happily navigate for your best outcome.

Fall Arrest Systems: How Fall Protection Compliance Differs Between Australia and New Zealand

While both Australia and New Zealand adhere to similar fall protection standards, their approaches to enforcement and…

Rethinking Seismic Anchors: A Smarter Approach for Interiors Engineering

Explore how Brevity is leading a smarter approach to seismic anchors in interiors engineering—balancing compliance,…

Navigating Interiors Engineering Challenges in New Zealand’s Education Sector: Key Considerations for Architects

Designing interiors for educational facilities in New Zealand requires a precise balance between safety, functionality,…